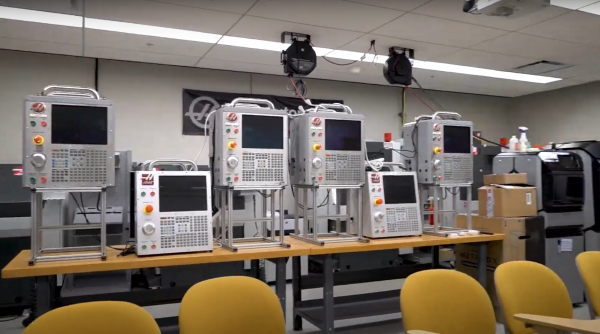

From taking classes in the Technical Education Center’s labs to programming machinery at a local manufacturing company, many skilled trade workers thrive in the workforce through apprenticeships. Such is the case for sophomore Faustino Lagunas, who is in the Applied Technology Certificate program. He is on the path to becoming a certified CNC Machinist through an apprenticeship facilitated by the College of DuPage. Lagunas described the complex role he performs at his workplace, Sternberg Lighting, where CNC Machinist workers program factory machines to produce complex light fixtures.

“We make lighting poles, the custom-made fancy ones that you see in towns or villages, not the normal poles you see on roads,” Lagunas described. “We do any modifications that standard workers can’t. On an average day, I get there and talk to my coworker for instructions. Before I was just doing assembly fixtures which is basically wiring things, like drivers for LED lights. Now I set up the machine, run parts, maybe even go on the manual end mill, where we insert the end mill or drill it.”

Lagunas began working at Sternberg Lighting before starting at COD in 2022. The plant manager of the company encouraged Lagunas to enter a trade program for CNC certification, so he could perform more complex work in programming the machines. Lagunas described how his workplace competencies have increased as he takes manufacturing courses.

“This fall semester I’m starting programming, which is the first step of what I was sent to school for,” Lagunas described. “I have my coworker helping. He’ll be vital for me to pass. Now I understand what he’s talking about at work, now that I’m going through COD, it’s making more sense when the teacher’s explaining. I know people that could probably learn CNC machining on the fly at work. But for me, I do need the textbook and the teachers. I’m definitely a school-learner.”

Lagunas is one of 11 other students currently in Manufacturing CNC apprenticeships through the College of DuPage’s Project Hire-Ed program. Project Hire-Ed partners with workplaces in a variety of fields, specifically those in the business and technical programs, to provide training and work experience to students.

The director of Project Hire-Ed, Danielle Kuglin Seago, explained how it is a Department of Labor Registered Apprenticeship Program and benefits both apprentice and employer.

“The Department of Labor Registered Apprenticeship Program designation provides strong support for apprentices with seven components that have structure and rigor to the training, competencies, wage increases and mentoring,” she said. “This means apprentices are receiving a quality apprenticeship program and will obtain a Department of Labor Certificate at the completion of the program, which is a national credential. Additionally, employers who support apprentices through a Department of Labor (DOL) Registered Apprenticeship Program are eligible for tax credits at the end of the fiscal year towards the costs of the apprentices tuition, books and fees, which the employer pays.”

Project Hire-Ed provides the students with career coaching in the first 90 days of the apprenticeship, periodic check-ins with case managers, and other tools. Lagunas described how he learned helpful skills from his caseworker, which aided him in balancing his classwork and apprenticeship.

“I think COD has helped me with all the resources they offer to students. The teachers are well-crafted in their knowledge,” Lagunas described. “The caseworker and tutoring are all very vital to try to overcome any obstacles you have to deal with. My caseworker, she’s always attentive, asking, ‘How are you doing? Is the apprenticeship going fine?’ She always sends someone to reach out to the employer, and the whole process is helpful for sure.”

Many of the courses in the Applied Technology Certificate are also geared towards competency-based education to ensure students have the necessary skills before going into apprenticeships, as Lagunas described.

“It’s been great. I took classes I never thought I would,” Lagunas said. “I’m not a computer guy, but I learned it this summer with an Introduction to Microsoft Office Technology class. It was probably the greatest thing I learned, and it’s personally helpful because I have other hobbies besides CNC work. I like ancient cultures, that’s what I study on my own time, and I want to write a book one day. So it goes further than what you’re learning for your job. It can help you with your personal life.”

The average GPA of graduating students who partook in the Project Hire-Ed apprenticeship was 3.47 GPA, which demonstrates the academic success of those who participate. There have been 75 apprentices in Project Hire-Ed so far, and most complete their program in about two years. Some employers may also choose to retain the student post-graduation, with 93% of the total Project Hire-Ed apprentices being retained.

As successful as Project Hire-Ed apprentices have been, Lagunas commented on the challenges he deals with between his demanding career, education and personal life.

“Between work, family and home, for me, I’m up to my knees with things,” Lagunas said. “I have kids going to college. Balancing life is a tough challenge. Especially too, when you’re at an older age compared to when you’re young with a little more energy. But the good thing is you get those things like tutoring and having a job that relates to your studies, like Solidworks that relates to engineering and drawing. I can go to people [at my company], talk to my coworkers and they say, ‘Yeah, I can definitely help you.’”

Kuglin Seago commented on how work conditions in some vocational jobs can be difficult, though many of the companies provide great work resources.

“Manufacturing can get a bad rap for being a dirty and dark workplace, but that’s contrary to what we often find when working with our local employers,” Kuglin Seago explained. “Many manufacturers have beautiful facilities that are clean and well-maintained, with features like ergonomic workstations, on-site gyms and kitchens, and foosball, ping pong and bean bags games for employees to use during breaks. Manufacturing has to battle negative preconceived notions of the industry and help re-educate the community on the career possibilities.”

There are also efforts around manufacturing to increase the diversity of candidates coming into the field through the DuPage County Youth Work-Based Learning Consortium, which approaches high school students to provide exposure to technical careers. The department is also working with regional advisory groups, like the DuPage Regional Manufacturing Advisory Committee, made of up local employers, trade workers groups and teachers.

Illinois recently received a $1.3 million grant, as part of the Bipartisan Infrastructure Law, to support its construction labor force and the development of Illinois energy-efficient infrastructure. The labor department seeks to increase training and employment opportunities for those who are underemployed or face challenges in entering trade school.

Lagunas said the grant can be a great career boost.

“The grant’s definitely crucial for someone who wants to start a career but doesn’t have that access or didn’t do well in school,” Lagunas said. “It’s vital to have some type of certificate degree in some type of trade. That’s the only way you can get your value paid of wage.”

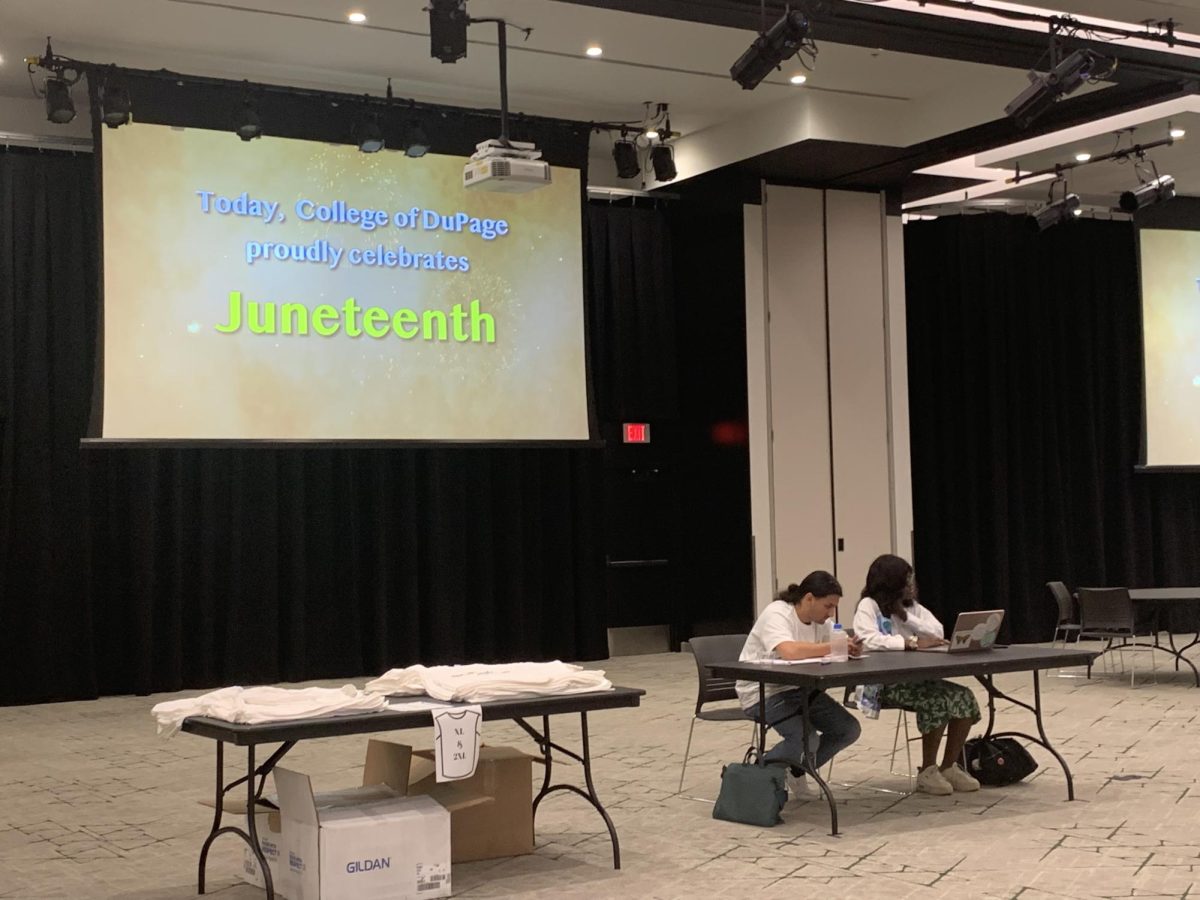

With Project Hire-Ed being beneficial for both students and employers, the grant could allow the program to grow more. It will also help to increase the equity and employment of underrepresented workers. The labor department is working with the Chicago Women in Trade group to bolster opportunities for women to enter trade apprenticeships, especially in construction.

Kuglin Seago said it is important to have more women and underrepresented people in these technical jobs.

“We are heavily involved with local manufacturers and expanding the number of women in this industry is a strong interest,” Kuglin Seago said. “Programs such as the Youth Summer Camp, Gadget Girls, help to expose girls to a career in manufacturing as a part of a summer camp at COD, supported by our manufacturing faculty and Continuing Education. I think it is important for women to have a strong mentor who is working in the field who can help them navigate the landscape and advocate for their needs in the workplace.”

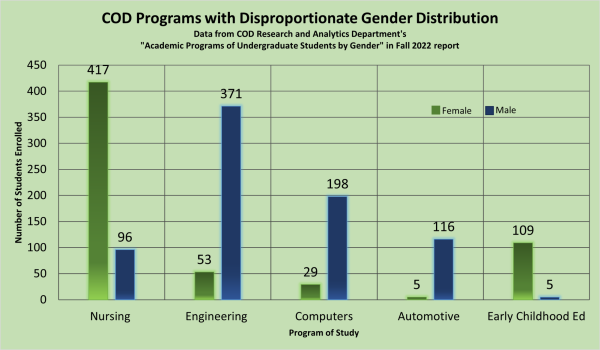

COD’s Research and Analytics department collected data on the number of male and female undergrads during the fall 2022 semester, in the Academic Programs with Highest Enrollment by Race and Gender report. Of the many programs Project Hire-Ed offers apprenticeships for, some have disproportionate divides by gender. The Nursing Associate program had 417 women and 96 men enrolled in the program that semester. Conversely, the Science Master Automotive Services Technology has 116 male students and 5 female students.

Students who are interested in pursuing apprenticeships through Project Hire-Ed can visit their website at www.cod.edu/project-hire-ed or contact them at [email protected].